For nearly three years after he became curious about non-petroleum

plastics, Cole Gibbs was engrossed with R&D.

“It was just: ‘Can we do this? Does this exist in the market? How can we

implement compliant solutions that are child-resistant for the

industry?’” he said of his search for a material to make containers for

the burgeoning cannabis industry.

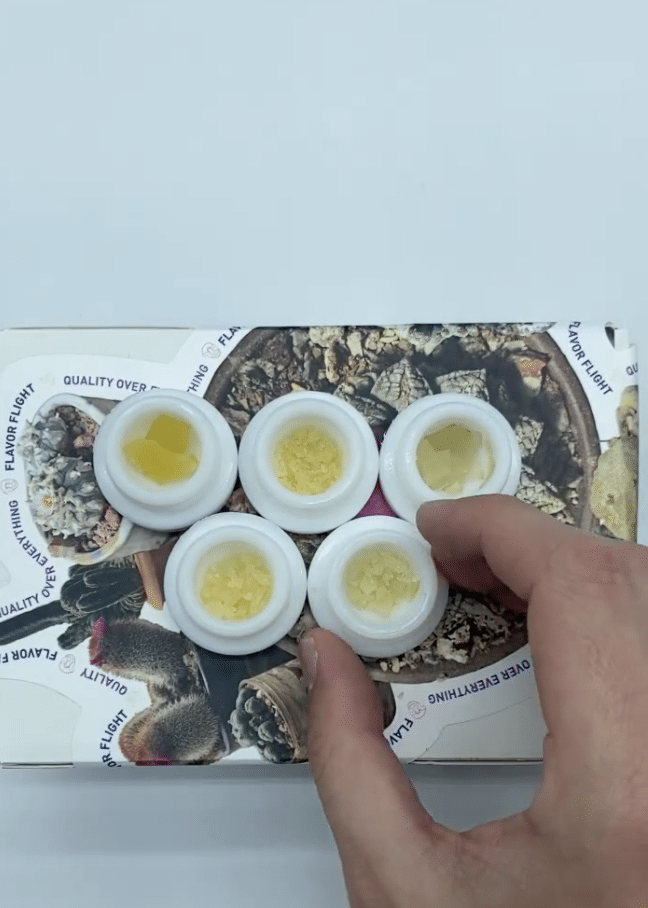

Gibbs’ intensity paid off, and in 2018 Dama Distributing was born.

Based in Aurora, Colorado, Dama launched the world’s first child-resistant container made from hemp plastic that is home/backyard compostable in December 2019.

Now Dama produces a range of cannabis containers made from bioplastics or infinitely recyclable materials like glass or steel.

The beauty of bioplastics is their lower carbon footprint, Gibbs said,

explaining that petroleum plastic produces 1.6 times its weight in

carbon emissions — and that hemp bioplastics sequester

carbon emissions because hemp is a carbon sink. Dama hemp plastic is

fully compostable, helping Gibbs meet his goal of producing products

that fit into a fully circular economy. The raw materials — mostly biowaste in the form of cannabis and hemp stalks — are sourced from a

network of farmers, he said.

Price was the biggest initial hurdle, Gibbs said, as bioplastics cost more

to produce than plastics made from petroleum. However, over time,

Dama has been able to lower prices and has educated vendors and

consumers about the advantages of bioplastics, Gibbs said.

Now, as consumers are increasingly willing to pay for sustainable

alternatives to petroleum plastics, Dama is seeing its sales increase.

Gibbs notes that customers have seen a 25% increase in sales and that

they can cover higher packaging prices by, for example, including two

prerolls instead of one in a container.

“The price difference is pennies, not dollars,” Gibbs said.

Gibbs emphasized the importance of educating consumers about

composting Dama’s products and noted that composting is becoming

more popular, with countertop compost containers and pickup services

in urban areas. Bioplastics break down either by solar degradation or

via microbes in the soil.

“People do like to test the results. They toss [a Dama container] in their

yard compost and a few months later they cannot find it again, so it

does work!” said Gibbs, who added that Dama works with hemp paper

producers to ensure labels will also biodegrade, making the entire

container compostable.

Gibbs now has his sights set on creating a bioscience facility under the

name Dama Bioplastics. A campaign is underway to ultimately raise $20

million for the facility, which would produce 100 to 200 tons per month

of bioplastic.

Gibbs points out that there are thousands of kinds of bioplastics.

“What works for sunglasses does not work for a bottle,” he said,

describing the company’s efforts to create a bioplastic cannabis

container. “We had to find the right polymer mix that meets child-

resistant and poison prevention requirements, and then [address] the

minute details required by the cannabis industry.”

Dama will continue to add bioplastic products to its lineup and will soon

launch direct-to-consumer items such as light fixtures made from hemp

waste, Gibbs said.

“Demand for bioplastics continues to grow,” he said. “The more we talk

to people, the more they understand the situation we are in with

plastic pollution, and the more they understand how we can solve that

problem.”

The post Dama Distributing Uses Bioplastics to Create Containers for Cannabis Industry first appeared on Let’s Talk Hemp.